I. TECHNOLOGICAL EQUIPMENT FOR BOTTLE IN PET BOTTLES 0.9 – 1.0 l.

1. Automatic linear blowing machine

Model: APF-6004

The concept of the APF-6004 blow molding machine is based on world standards for the productivity of this class of machines – 1,500 bottles / hour from one place in the blow mold, and also complies with the norms and directives of the European CE quality standard and the requirements of the HACCP food industry.

Equipment:

• The patented system for closing the mold allows to significantly reduce the time cycle of bottle formation and thereby guarantee high productivity of the machine;

• The automatic controller of temperature control and adjustment with feedback through the sensor of the omron trademark (Japan) has been introduced into the logic controller of the Austrian company b & r;

• The constructive concept of the blowing machine allows using a large number of mold sets to produce a wide range of pet bottles on one machine with minimal changeover times

• A recuperation system with reuse of compressed air from a high-pressure line in the mechanism control system can save up to 25% of the cost of compressor equipment.

• An intensive preform heating system consisting of infrared lamp modules with a 2000 and 1000 W reflector and 8-zone temperature control, each of the eight zones of three heating modules has the ability to independently shut off for blowing asymmetric bottles of complex shape with a non-standard surface topography;

• The innovative system of forced air cooling allows you to evenly distribute the temperature from the outer wall of the preform to the inner one, which eliminates the percentage of rejects;

• An improved system for loading the preform into the furnace, eliminating its incorrect orientation and jamming;

• For the apf-6004 model, a servo drive was used in the mechanism for transferring the heated preform to the blow mold

• A separate valve block is used for each blowing slot

Additional fine adjustments to the blowing process, including a change in the speed of the tension rod,

• Use of polyurethanes and elastomers with improved performance;

• Sophisticated, highly efficient cooling systems for blow molds are ensured by the use of components from d-m-e (usa belgium);

• An orientator with a return unit to the hopper of a non-oriented pet preform

• All exposed parts of the equipment are protected by a casing or plexiglass cladding elements in accordance with European food industry standards.

Technical data:

Productivity boot / hour to 6000

Number of seats in the mold pcs. 4

Bottle capacity l 0.50 – 2.0

Blowing pressure bar up to 40

Air pressure bar 8 – 10

for pneumatic cylinders

Compressed air consumption m³ / min 7

for blowing

Compressed air consumption m³ / min 2

for pneumatic cylinders

Coolant Temperature ° C 7-9

Supply voltage 400V / 50Hz

Installed power kW 52

Overall dimensions mm 8660х3240х2540

2. Air conveyor

Model: IND- Trans 71 Aero

Designed for transporting empty bottles. Stainless performance. Air Filtration Class: G4

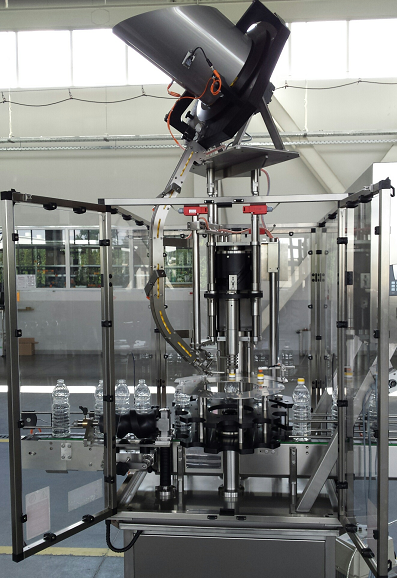

3. Monoblock of weight filling and capping

Model: IND-Dose 49 RWTC 12/4 Pragmatic®

Rotary filling monoblock for filling oil in PET bottles and capping with printed caps. The monoblock uses the most advanced technology to measure the exact weight during bottling. Filling takes place through a special patented valve, which provides a laminar flow of the product and prevents the formation of the last drop.

Бутылки транспортируются за горло. Переналадка моноблока для

Bottles are transported by the throat. Conversion of the monoblock for a different size of the cylindrical bottle is carried out with minimal replacement of the format parts.

Technical specifications:

Performance:

– in the format of 1 liter but. / hour up to 6,000

Dosing accuracy g ± 1.5

Dosing limits g from 200 to 2000

Bottle diameter mm to 130

Power Supply V / Hz 380/50

Installed power kW 5

NB: To ensure bottling performance, 30 millimeters of space is required between the level of the product and the neck of the bottle.

Monoblock composition: • Rotary metering carousel. The product is poured by 12 electronically controlled special valves (nozzles), which ensure the product is bottled by gravity-laminar flow without contact between the filling valves (nozzles) and the neck of the bottle. The accuracy of the spilled product is ensured by closed-type weight sensors made of stainless steel.

Stainless steel casing column with cover orientator and 4 capping heads.

The monoblock includes:

• Stainless steel case;

• Safety perimeter – free-standing safety guards made of safety glass with all necessary safety and safety switches according to CE;

• Maintenance – fully open security doors provide easy access to all parts of the machine and the ability to clean the floor under the supporting structure;

• Drives: gear motors of the company Lenze – Germany;

• All pneumatic components of the SMC company – Japan;

• Filling column with 12 weight sensors;

• Food tank .;

• Sensor for monitoring the level of the product in the tank;

• Thermometer in the incoming product pipeline;

• 4-position rotary capping column with an orientator for caps;

• The function “no containers – no filling”; “No packaging – no capping”;

• Intelligent management – Touch screen, menu in Russian, PLC (OMRON); control algorithm and software developed by Index – 6 specialists, provide an opportunity for simple handling of equipment, self-diagnosis;

Benefits:

• Silent and smooth operation of the machine;

• Lack of product bottling;

• High dosing accuracy;

• Lack of contact between bottles and filling nozzles.

The monoblock includes a scraping device for checking the weight / volume for given boundaries. PET bottles that are larger and smaller in weight / volume and which do not have a cap are rejected and automatically fed to a parallel conveyor.

4. Labeling machine for packing one circular polypropylene label

Model: IND-GM 360 Automatic rotary labeling machine, equipped with one hot glue station. Designed for gluing one circular label of polypropylene (roll) on cylindrical bottles.

Productivity boot / hour to 8000

Max. container diameter mm 110

Max. label height mm 115

Max. label length mm 350

Max. roll diameter mm 340

Installed power kW 6

Compressed air consumption 6 bar m3 / h 25

Structure:

• Basic support frame and general structure – the support frame is made of reinforced steel welded profiles and equipped with height-adjustable support posts. The casing is equipped with side inspection doors and side coverings made of AISI 304 stainless steel sheet.

• Stainless conveyor box.

• Emergency barriers are installed around the entire perimeter of the base frame of the machine. The barriers are made of AISI 304 stainless steel and equipped with windows made of transparent material. All electrical, pneumatic and control circuits are built in accordance with the latest accepted international standards (EU Standards).

• The main carousel with 12 self-centering platforms for containers, which provide the perfect location for bottles; the surface of the platforms has anti-friction rubber to prevent the bottles from slipping during the operation. The rotation of the platforms is transmitted by a timing belt and rollers.

• Label gluing station – equipped with one caliper for reels with labels, complete with a device for controlling film tension. The film feed roller is driven by an independent electric motor that adjusts the speed supply according to a certain mark or recognition mark on the film and depending on the production speed of the machine through the encoder. Labels are cutthrough the mechanical interaction of one static knife and one rotational knife; adjustment and adjustment are extremely easy. Fine tuning is necessary to ensure the long life of the knives.

• Control panel – stainless;

• To increase accuracy and reduce noise levels, the machine is equipped with a linear transmission system with drive gears made of C40 steel and polyamide.

5. Inkjet printer

Model: Videojet 1220 For applying information (date, expiration date, etc.) to the bottle.

Row pcs 3

Character height mm 2-8

6. Conveyor system

Model: IND- Trans 71

The system allows the movement of bottles through the bottling line. Made from AISI 304 stainless steel.

Equipment:

• motors – Lenze;

• sensors – Ifm electronics;

• conveyor components – Movex / Systemplast.

7. Semi-automatic box closing machine

Model: S8

The machine is designed for semi-automatic closing of the upper and lower petals of the box with self-adhesive tape, manual adjustment for boxes of various sizes. Sizes of a box:

– Max. L ∞ W 400 mm H 400 mm

Benefits:

– Simple handling

-Fast start

– Easy setup

II.TECHNOLOGICAL EQUIPMENT FOR PET FILLING in 5.0 l.

1. Semi-automatic PET Bottle Blowing Machine

Model: I-PET-10

Technical data on bottles and preforms

bottles:

maximum volume l 11

maximum diameter mm 250

maximum height without neck mm 450

preforms:

minimum / maximum length mm 60/210

maximum internal body diameter mm 13

maximum throat internal diameter mm 13

maximum body wall thickness mm 4.2

performance:

nominal for a bottle of 5 liters (two nests)

(depending on bottle shape and preform) 400 bottles / hour

Machine data

Required workspace m 3 x 3

Height mm 1950

Machine weight kg 740

Carrier Account for Preforms 29

The account of the heating blocks 2

Counting of heating zones 8

Blowing position score 2

Necessary nutrition

Chilled Water:

Bar 5.5 pressure

recommended temperature oC 10

required flow rate m3 / hour 1.5

cooling capacity kcal / h 3 000

Compressed air:

operating pressure Bar 9.5

air flow rate for operating pressure

(at maximum productivity) l / min 400

Bar Blow Pressure 16-20

air flow rate for blowing (maximum) l / min 1100

Electricity:

Voltage 3 x 380 V (50 Hz)

Voltage controllers V 24

Permissible deviations in voltage + 10 / -10%

Installed power kW 32

Installed power for heating kW 32

Maximum power consumption kW 13

2. Linear piston metering machine

Model: IND-Dose 42VP-4G

Linear piston dosing machine with 4 filling nozzles. All parts in contact with the product are made of AISI 304 stainless steel.

Pneumatic drive machine.

Performance

– oil 5 l but / hour up to 350

Dosing limits cm³ 500 ÷ 5000 *

Packing diameter mm max. 180

Package height mm max. 350

Nutrition:

– electric V / Hz 380/50

– compressed air 6-8 bar N / min 100

Installed power kW 0.5

* 5l bottles are filled in two cycles

Structure:

• Stainless steel frame, tightly enclosed polycarbonate guards;

• Closed car chamber with a ceiling;

• No tare function – no filling;

• Hygienic clamps for all connections;

• Submersible filling heads with pneumatic drive;

• 4 dosing cylinders for volumetric filling of the product;

• Automatic internal washing of the storage tank and dosing tract;

• Food tank with internal surface roughness

Below Ra 0.8:

– hermetically sealed;

– wide control hatch;

– potentiometric level sensor;

• Butterfly-type hygienic valves for product and cleaning solution;

• Control panel – stainless; Touch-screen control, PLC with an interface in Russian;

• Pneumatic components SMC.

3. Capping machine

Model: IND-Close 11 G The machine is designed to automatically seal PET bottles with plastic screw caps. The covers are automatically installed using the mounted orienting device.

Productivity boot / hour to 1000

Diameter of caps mm

Bottle diameter mm to 180

Bottle height mm as per model

Power – Electric V / Hz 380/50

Installed power kW 1.5

Overall dimensions LxBxH mm 2000х1200х2600

Weight kg 700

Elevator 200 kg.

The composition of the machine:

• Stainless steel frame, tightly enclosed guards;

• Orienter for covers;

• Tray for covers;

• Pick-and-place system;

• One-position casing string with 1 head and hysteresis clutch for smooth regulation of capping force;

• Conveyor box 2m (without drive).

4. Labeling machine

Model: IND-Lab 31 GThe machine is a linear type, designed to automatically adhere one self-adhesive label to PET bottles

Productivity boot / hour to 2000

Label height mm up to 160

Label length mm up to 200

Packing diameter mm up to 180

Power Supply V / Hz 380/50

Installed power kW 1,15

The composition of the machine:

• Stainless steel frame;

• conveyor;

• Inlet distribution module for packaging;

• One labeling station HERMA Germany; the etiquette station is adjusted along the X-Y-Z axes and around its axis;

• Electric motors Lenze;

• Stainless steel shield.

5. Conveyor system for bottles

Model: IND- Trans 71

The system ensures the movement of bottles through the bottling line, ensuring uninterrupted operation of the line. Made of AISI 304 stainless steel.

• motors – Lenze;

• sensors – Ifm electronics;

• conveyor components – Movex / Systemplast.

6. Semi-automatic box closing machine

Model: S8

The machine is designed for semi-automatic closing of the upper and lower petals of the box with self-adhesive tape, manual adjustment for boxes of various sizes.

Sizes of a box:

– Max. L ∞ W 400 mm H 400 mm

Benefits:

– Simple handling

-Fast start

– Easy setup